Huge vs small. Straight vs curved. Size and shape matter. Especially in the world of farming, where it affects the bottom line in a big way.

The price commercial farmers get for any crop is based on current market “commodity” prices. But, they can’t sell the entire crop for that price. Why? Because some crop prices are based on size and shape.

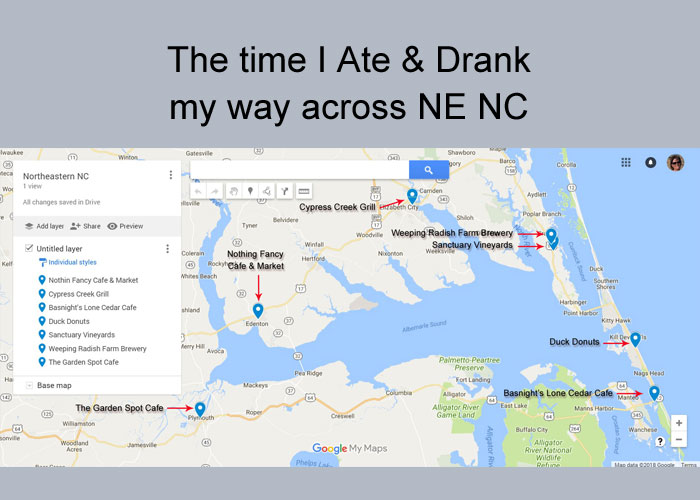

I spent time at a couple of farms last month, learning about crops, pricing, and the realities of farming.

AJ Smith and Sons Farm in Edenton, NC

The farm was started by AJ Smith and is now run by his four sons and several grandsons. We met one of each, Jeff Smith and one of his sons.

The farm is extremely diversified. They grow clary sage (the oil is used in Channel perfume), peanuts, soybeans, corn, watermelons, cucumbers, and snap beans. They also have cattle and hogs.

I actually brought my travel bottle of Channel #5 so I could get a picture of it with the clary sage. Unfortunately we just missed the harvest, so no joy for #5.

Our group was looking at cucumbers – from field, to harvest, to prepping for sale. Did you know the thin coating of wax on cucumbers keeps them fresh longer? I didn’t! And I was surprised to learn about the difference in sale price based solely on cucumber shape.

This fresh-picked NC cucumber [pictured below] may bring a smile to your face, but not the farmers. Did you know farmers receive $6 per box of cucumbers with this shape because consumers want them straight? Same taste, different shape costs the farmer $6 per box, since a box of straight cucumbers brings $12.” ~ Heather Lifsey Barnes

One thing that was pretty amazing to me was how clean the open “barn” processing area was. It’s not a new building, either. Even the rafters on the 1 1/2 – 2 story high ceiling are cleaned regularly. I looked, and couldn’t find any dust or cobwebs!

I loved listening to Jeff talk about the history of the farm and the family involvement over the years.

John E Ferebee Farming, Inc. in Camden, NC

This seventh (eighth on deck) generation family farm focuses on potatoes, each year growing and packing red, white and yellow flesh potatoes they grow on 3,800 acres. Their potatoes are shipped across the United States and parts of Canada.

John E. “Ed” (6th gen) Ferebee’s daughters, Martha Ferebee and Susan Jennings, are running things these days. Martha took time out to show us white potato harvesting in the field, trucks unloading, the cleaning and sizing process, packaging and their pre-shipping collection area. As soon as the white potato harvest is done, the yellow potato harvest begins.

She explained the various sizes and their different values based on size. I thought it was interesting that the extra large, aka huge, potatoes are labeled “Chef” potatoes. And that’s who they go to. You’ve probably had one when you ordered a baked potato at a restaurant. The smallest potatoes are the most sought after and fetch the highest price.

We got a close up look at various packaging machinery which is extremely expensive, but well worth it in savings over time. The entire potato harvest takes only 4 to 5 weeks, so machinery cuts back on labor hours and increases daily output. Their goal is to dig, pack, and ship in one day.

Martha explained the coding on bag clips: date, farm, and field the potatoes came from. If there’s ever an issue with their potatoes, they’ll know exactly where and when they were harvested, so it’s a good place to begin investigating.

Next time you’re in the grocery store produce section, take a moment to think about the journey each cucumber, potato, or whatever it is you’re buying, has made from farm to store, and the people who grew it. If you read the little labels on each peace of produce, you’ll see where it’s from.